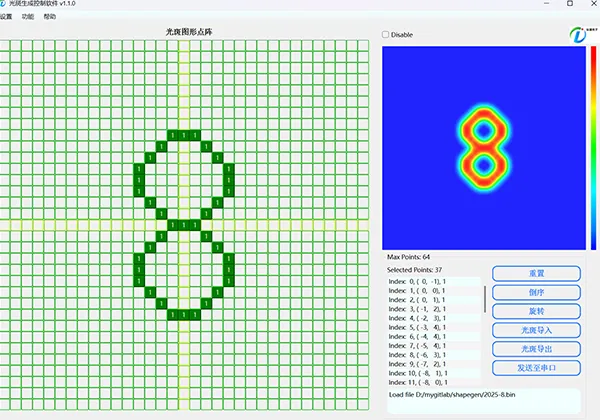

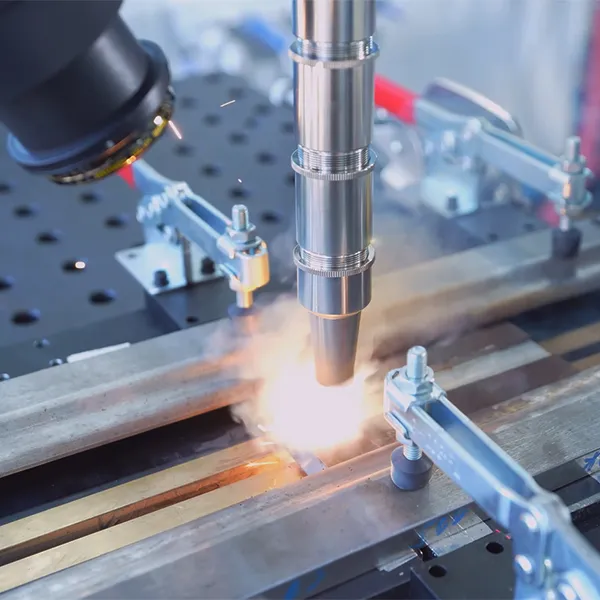

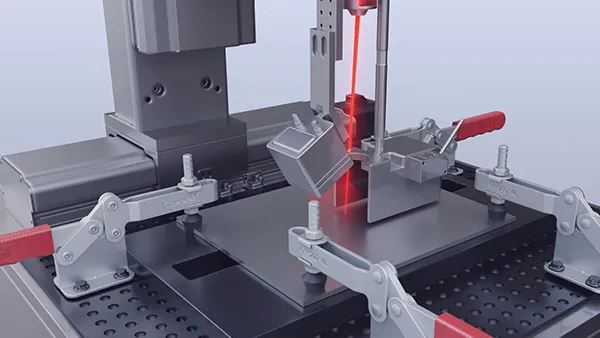

Multi-functional Integrated Laser Workstation for Laser Cutting/Welding/Additive Manufacturing

- Typical Scenarios

Integrated additive/subtractive manufacturing equipment, automotive production lines with integrated cutting and welding, and Industry 4.0 flexible production line demonstration projects . It is also perfect for laser material processing R&D and teaching labs and optical field-controlled laser material processing R&D centers.

- Main Advantages

High-speed dynamic beam shaping ensures seamless, multi-functional integration.

Closed-loop management of power, beam quality, and spot morphology allows for traceable quality.

A built-in optical field control device provides real-time compensation for thermal distortion.

Dynamic beam shaping ensures processing error compatibility across laser cutting, welding, and additive manufacturing.

High-Energy Laser Phased Array/Coherent Synthesis/Spectral Synthesis

- Typical Scenarios

Coherent synthesis, spectral synthesis, and high-energy phased array lasers. Also suitable for coherent/spectral hybrid synthesis high-energy lasers.

- Main Advantages

High spectral brightness: single-fiber single-mode output of 10kW with a linewidth less than 100GHz.

Built-in optical field control devices compensate for distortion in the synthesis optical path.

Achieves efficient coherent/spectral synthesis without the need for an optical axis pointing adjustment mechanism.

Delivers high-efficiency phased array coherent synthesis without the need for sub-aperture beam shaping devices.

Laser Directional Energy/Transmission Systems

- Typical Scenarios

Laser C-UAV, C-RAM, coherent laser radar, air-to-ground laser communication, and remote laser energy transfer charging.

- Main Advantages

The built-in MHz frequency optical field control device compensates for atmospheric turbulence and mechanical jitter.

Suppresses speckle and atmospheric scintillation during coherent imaging to improve quality.

Compensates for turbulence in communication to increase bandwidth and lower the bit error rate.