Laser Welding System

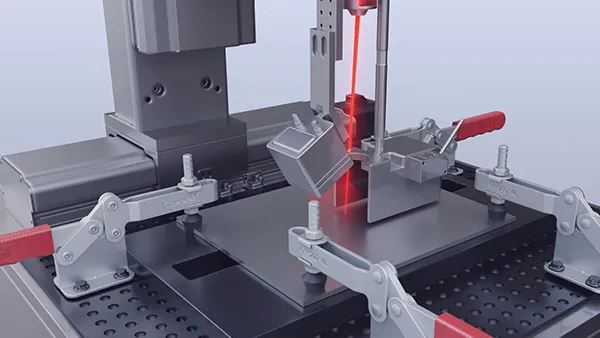

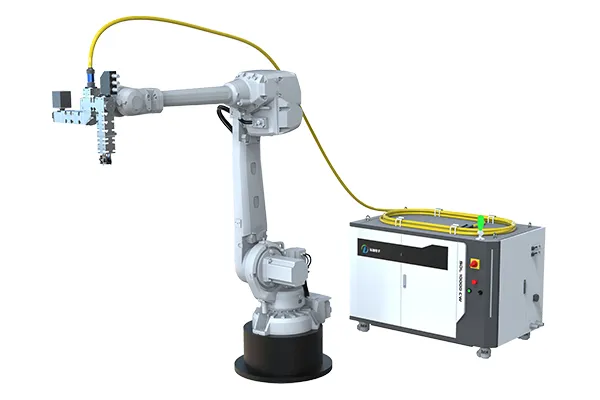

CPL-10000- RW/GW Medium-Thickness Steel Autogenous Laser Welding System

Robotic welding system for the autogenous welding of thin to medium-thickness steel of up to 20mm

Laser Welding System

CPL-10000- RW/GW Medium-Thickness Steel Autogenous Laser Welding System

Robotic welding system for the autogenous welding of thin to medium-thickness steel of up to 20mm

CPL-10000-RW/GW medium-thickness steel autogenous laser welding system is built around a 10kW-class full-vector optical field-controlled fiber laser. It integrates a "5-in-1" in-weld monitoring sensor and a real-time laser welding control platform. With modular and configurable laser welding software, the system is capable of handling complex working conditions, solving key challenges in medium-thickness plate laser welding—such as alignment tolerance and welding defects. It enhances welding quality, effectively mitigates common defects like pores, cracks, and undercutting, and improves weld strength and fatigue life.