-

- Fiber Laser Beamsplitter Module Beam splitting for the analysis and comparison of fiber laser optical parameters

-

- Laser Collimation Module Calibrator Collimation testing and calibration of laser beams through CMOS spot profile analysis

-

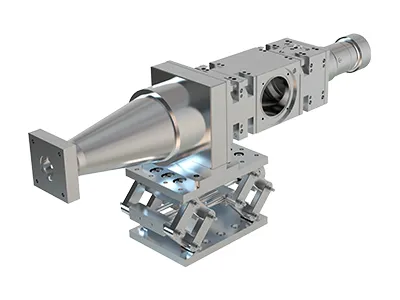

- Laser Beam Quality Analyzer Measurement of laser beam profile, beam width, beam shape, M² factor and divergence angle in laser welding

-

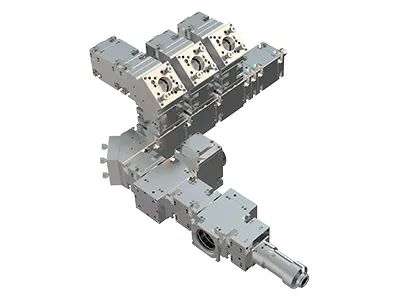

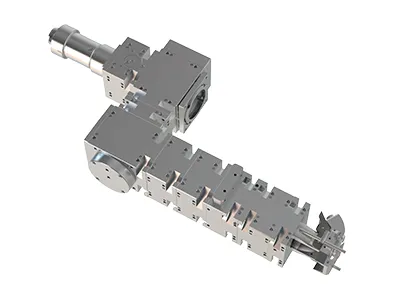

- Modular Laser Welding Head Laser processing head with a power up to 15kW for welding tasks requiring long focal length and short working distance

-

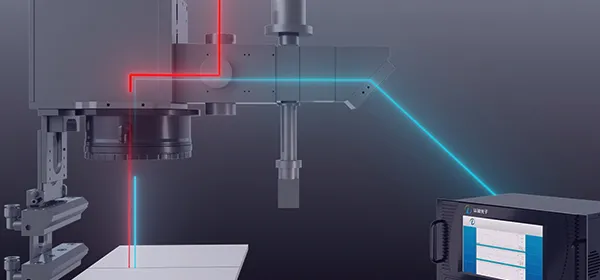

- Real-time Laser Process Monitoring Module Online process monitoring of laser power and spot profile in laser welding, cutting and marking operations

-

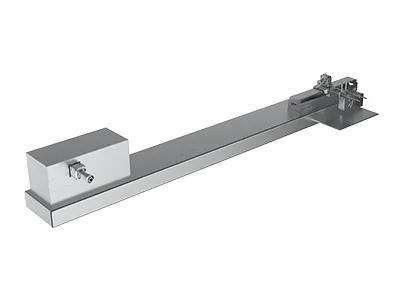

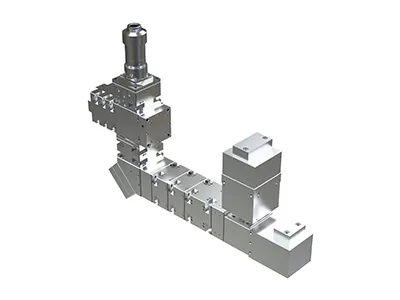

- Laser Welding Position Compensation System Precise adjustment and compensation of workpiece positioning tolerances

Reach out today for expert support

Discover how our software-defined lasers and smart laser welding systems can help your production.

Contact Us

Laser Welding System

What do you recommend for evaluating the beam quality of a high-energy focused laser from a welding head?

What do you recommend for evaluating the beam quality of a high-energy focused laser from a welding head?

We recommend our laser welding head beam quality analyzer, specifically designed to evaluate the quality of high-energy focused laser beams. It can measure the static and dynamic beam quality from the laser processing head in real time, accurately assessing metrics such as intensity profile, beam width, shape, and focal position. It supports laser powers of up to 20kW, meeting the demands of high-power applications.

We perform welding operations on pipes for petroleum exploration. Which welding head is suitable for this?

We perform welding operations on pipes for petroleum exploration. Which welding head is suitable for this?

Our ten-kilowatt long-focal-length short-working-distance laser welding head is an excellent choice. This welding head, composed of a collimation module, a focusing module, and a shielding gas module, supports weld seam monitoring, spot morphology analysis, and power measurement. It comprehensively enhances the precision and controllability of the welding process. Both the collimating and focusing lens groups are customizable to meet specific weld seam width and back-working-distance requirements.

In engineering, the actual weld seam position often deviates from the preset path. What solution do you have for this?

In engineering, the actual weld seam position often deviates from the preset path. What solution do you have for this?

Our position compensation laser welding system is an intelligent welding solution that solves this issue by combining a real-time weld seam position sensor with a high-speed galvanometer. The system quickly compensates for positional deviations, ensuring the laser beam is always aligned with the center of the weld seam and preventing welding defects caused by positional inaccuracies.