Laser System Modules & Measurement Instruments

CPL-6000-CW/GW Laser Welding Position Compensation System

Precise adjustment and compensation of workpiece positioning tolerances

Laser System Modules & Measurement Instruments

CPL-6000-CW/GW Laser Welding Position Compensation System

Precise adjustment and compensation of workpiece positioning tolerances

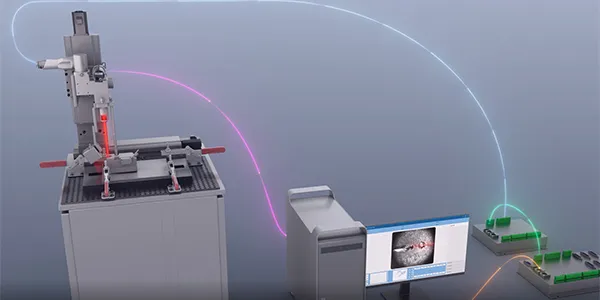

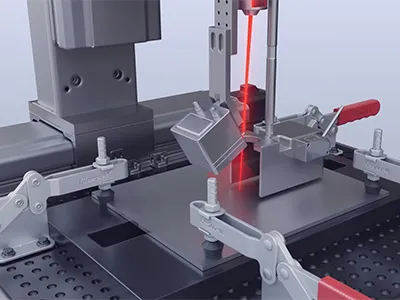

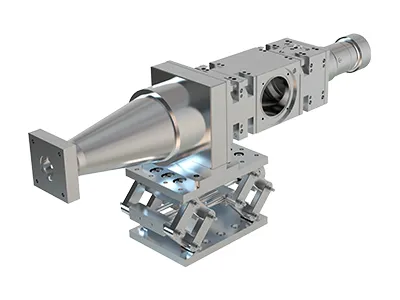

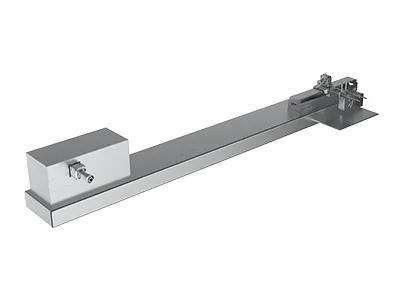

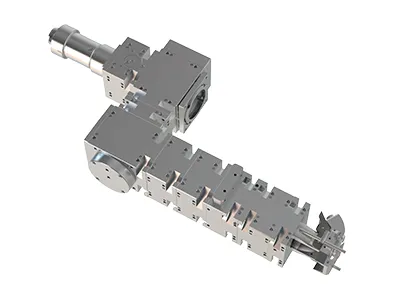

During the laser welding process, deviations between the actual weld seam position and the preset path can occur due to workpiece processing errors, assembly errors, or thermal deformation. The laser welding position compensation system compensates for these deviations, ensuring the laser beam is always aligned with the center of the weld seam and preventing welding defects (such as lack of fusion or misalignment).

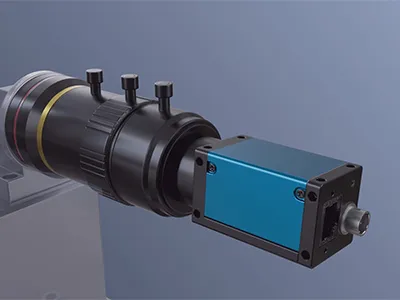

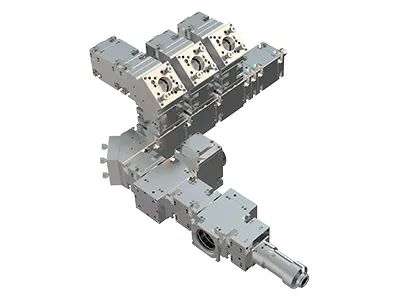

This intelligent laser welding position compensation system captures the weld seam position in real time and uses a galvanometer to quickly compensate for position deviations. Its main components include a 6000W or lower-power laser, a programmable digital galvanometer module, a vision detection module, a real-time PID control module, an XYZR four-axis CNC motion mechanism, and a configurable welding software system. By controlling the high-frequency digital galvanometer to deflect the laser beam, the system keeps the laser beam stably centered on the weld seam. Simultaneously, the system calculates changes in the weld seam gap and adjusts the actuator to optimize the welding effect. This laser welding position compensation system is suitable for welding tasks involving multiple materials and conditions, optimizing laser energy distribution and the solidification process of the melt pool to effectively reduce the occurrence of defects such as undercutting, pores, slag inclusions, and cracks.