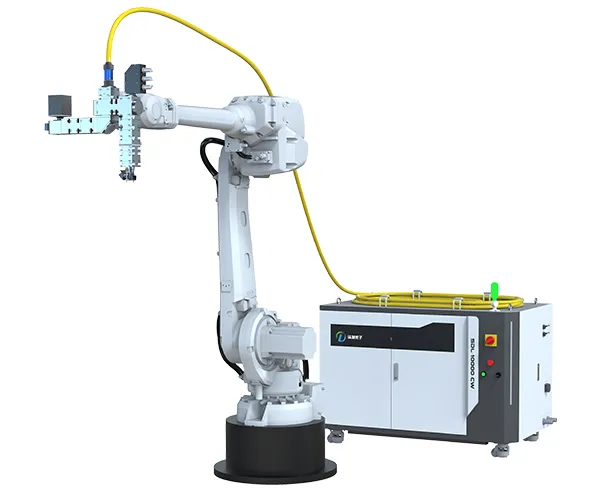

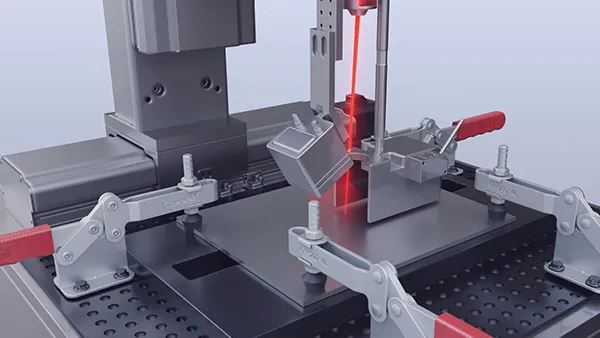

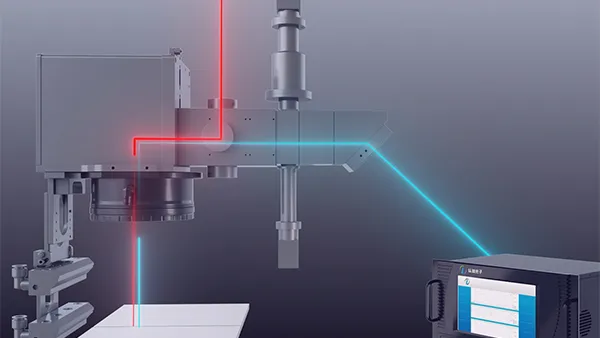

Laser Welding System

CP Laser offers a range of advanced welding solutions designed to tackle complex challenges in industrial manufacturing. Our systems are engineered to improve weld quality, enhance efficiency, and reduce common defects.