FAQs

What types of companies use the company's laser welding equipment?

What types of companies use the company's laser welding equipment?

Manufacturing companies with welding needs for aluminum alloys, die-cast aluminum alloys, or dissimilar metal materials, as well as those requiring high-quality welding of medium-thickness steel, are among our customer base. This also includes research institutions focused on lasers or welding.

What types of product customization requests can the company accept?

What types of product customization requests can the company accept?

The company provides customization services for fiber laser array coherent synthesis and phased array laser products and modules with different laser wavelengths, array sizes, and powers.

What technical breakthroughs do the company's products represent?

What technical breakthroughs do the company's products represent?

The company leverages two core technologies—full-vector optical field-controlled fiber lasers and cognitive intelligent control—to expand the laser weldability and process parameters of metal materials, while also shortening the time for laser welding parameter optimization to just a few minutes.

What after-sales services are available?

What after-sales services are available?

- Remote online installation and after-sales service support.

- On-site installation and after-sales service support.

- Spare parts services for equipment.

- Standby machine services.

- Online or offline technical training, providing comprehensive instruction on product or system installation, operation procedures, maintenance, and process adjustments.

How can we achieve the desired efficiency and penetration depth when welding 20mm thick steel plates?

How can we achieve the desired efficiency and penetration depth when welding 20mm thick steel plates?

Our software-defined fiber laser is based on phased-array technology, enabling a user-definable, sortable, and switchable laser spot shape with a scannable focal point. Its high power, high beam quality, and high dynamic beam shaping frequency, combined with a real-time focus correction feature, allow a single-mode laser to achieve twice the depth of focus.

How can we address spatter and incomplete fusion during die-cast aluminum welding?

How can we address spatter and incomplete fusion during die-cast aluminum welding?

Our 5-in-1 laser welding process monitoring sensor provides real-time spatter identification. Using a high 100MHz sampling frequency, it captures sudden changes in light intensity caused by spatter. A machine learning algorithm then differentiates between normal and abnormal spatter, linking to the laser to reduce power and prevent incomplete fusion.

How can we achieve real-time compensation for weld pool fluctuations during thick plate welding to ensure a uniform weld seam?

How can we achieve real-time compensation for weld pool fluctuations during thick plate welding to ensure a uniform weld seam?

Our real-time inference control platform is a highly efficient and stable system specifically developed for closed-loop laser welding control. By integrating image acquisition, spectral analysis, and real-time inference algorithms, the platform supports sub-millisecond latency from feedback to control, meeting the real-time needs for managing the intense fluctuations of the melt pool and keyhole during laser welding and additive manufacturing processes.

What are the key differences between a software-defined laser and a conventional industrial laser?

What are the key differences between a software-defined laser and a conventional industrial laser?

This software defined fiber laser stands out with its multiple advantages, including a high power of 80kW, a high beam quality of 1.2 times the diffraction limit, and a high dynamic shaping frequency of 10MHz. These features enable a definable, orderable, and switchable laser spot morphology with a scannable focus.

What is the practical significance of the "Three Highs" in a software-defined laser?

What is the practical significance of the "Three Highs" in a software-defined laser?

The high beam shaping frequency is a core, irreplaceable advantage in metal welding, as it solves the welding challenges of steel, aluminum alloys, and die-cast aluminum parts with thicknesses over 10mm.

How does the laser achieve output spot control?

How does the laser achieve output spot control?

The laser utilizes multi-channel phase control to achieve coherent synthesis for high beam quality output. By adjusting phase control parameters via high-speed FPGA circuits, the coherent position can be changed, allowing for spot transformation to any location and ultimately forming a spot of any shape.

How does the laser ensure high-quality welding?

How does the laser ensure high-quality welding?

The 10kW laser's high beam quality enables deep thermal penetration, forming a stable weld pool for thicknesses over 10mm. This, combined with high-dynamic spot adjustment, significantly reduces spatter, pores, and cracks, resulting in consistently high-quality welds.

How is the long-term stability of the beam quality maintained?

How is the long-term stability of the beam quality maintained?

The all-vector light field regulated laser maintains a beam quality close to the diffraction limit. It uses 24 optical fibers to simultaneously modulate a user-defined spot. Its stability is more easily maintained compared to traditional lasers.

Will the laser power decay during long-term operation?

Will the laser power decay during long-term operation?

The service life of a fiber laser is determined by its pump source, which typically exceeds 100,000 hours. This laser utilizes a closed-loop control system and multiple sensors to perform real-time inference on key welding parameters, ensuring both short- and long-term process stability.

We are building a high-power laser system and facing power limitations due to Stimulated Brillouin Scattering (SBS). Which device can solve this?

We are building a high-power laser system and facing power limitations due to Stimulated Brillouin Scattering (SBS). Which device can solve this?

Our tunable narrow linewidth laser seed source integrates a single-frequency PM fiber laser, a wide-bandwidth electro-optic phase modulator, and a driver circuit. By applying a specific RF signal to the single-frequency seed light via the modulator, the spectral width is successfully expanded from kHz to the 100GHz range, effectively suppressing the SBS effect that can occur during high-power amplification and thereby increasing the output power.

We need to build a coherent laser synthesis system that requires exceptional amplification and environmental adaptability. What do you recommend?

We need to build a coherent laser synthesis system that requires exceptional amplification and environmental adaptability. What do you recommend?

Our 4-channel narrow linewidth low-noise pm fiber amplifier array is a core component of our next-generation low-noise fiber amplifier systems. It features an integrated opto-electro-mechanical design with four independent high-performance PM fiber amplifier channels. This module offers exceptional amplification with a total power of 80W. The standard version operates stably across a wide temperature range of -5°C to +45°C, and a military-grade reinforced design is available for extreme environments.

Our industrial site has multiple lasers that require real-time monitoring. How can we ensure data acquisition efficiency and equipment safety?

Our industrial site has multiple lasers that require real-time monitoring. How can we ensure data acquisition efficiency and equipment safety?

CP Laser's multi-node data acquisition and interlock protection system is specifically designed to meet the complex challenges of data acquisition and safety interlocks in industrial environments. It supports up to 100 nodes, meeting the needs of large-scale industrial sites. When sensor data exceeds a preset threshold, the system automatically triggers an alarm signal, ensuring equipment and production safety.

What do you recommend for evaluating the beam quality of a high-energy focused laser from a welding head?

What do you recommend for evaluating the beam quality of a high-energy focused laser from a welding head?

We recommend our laser welding head beam quality analyzer, specifically designed to evaluate the quality of high-energy focused laser beams. It can measure the static and dynamic beam quality from the laser processing head in real time, accurately assessing metrics such as intensity profile, beam width, shape, and focal position. It supports laser powers of up to 20kW, meeting the demands of high-power applications.

We perform welding operations on pipes for petroleum exploration. Which welding head is suitable for this?

We perform welding operations on pipes for petroleum exploration. Which welding head is suitable for this?

Our ten-kilowatt long-focal-length short-working-distance laser welding head is an excellent choice. This welding head, composed of a collimation module, a focusing module, and a shielding gas module, supports weld seam monitoring, spot morphology analysis, and power measurement. It comprehensively enhances the precision and controllability of the welding process. Both the collimating and focusing lens groups are customizable to meet specific weld seam width and back-working-distance requirements.

In engineering, the actual weld seam position often deviates from the preset path. What solution do you have for this?

In engineering, the actual weld seam position often deviates from the preset path. What solution do you have for this?

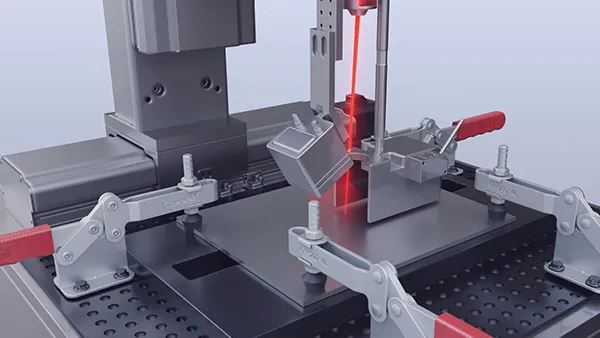

Our position compensation laser welding system is an intelligent welding solution that solves this issue by combining a real-time weld seam position sensor with a high-speed galvanometer. The system quickly compensates for positional deviations, ensuring the laser beam is always aligned with the center of the weld seam and preventing welding defects caused by positional inaccuracies.

Our shipbuilding company needs to weld 20mm thick marine steel plates, but traditional methods often result in pores and lack of fusion. Do you have a solution?

Our shipbuilding company needs to weld 20mm thick marine steel plates, but traditional methods often result in pores and lack of fusion. Do you have a solution?

Our medium-thickness steel autogenous laser welding system is the ideal solution. Built around a ten-kilowatt full-vector optical field-controlled fiber laser, it integrates a "5-in-1" in-weld monitoring sensor and a real-time laser welding control platform. This system solves alignment tolerance and welding defect challenges in medium-thickness plates, improving weld quality and effectively mitigating common defects like pores, cracks, and undercutting, while also increasing weld strength and fatigue life.

Our new energy vehicle battery factory needs to weld aluminum alloy water-cooling plates. Traditional welding is slow and causes significant deformation. What products do you recommend?

Our new energy vehicle battery factory needs to weld aluminum alloy water-cooling plates. Traditional welding is slow and causes significant deformation. What products do you recommend?

Our large-format aluminum alloy galvanometer welding system is an intelligent laser welding solution specifically designed to address low efficiency, control difficulties, and high costs in ultra-large-format laser planar welding. This system supports a maximum processing area of 1.2m×1.2m and is suitable for the precision welding of materials such as aluminum alloys, die-cast aluminum, stainless steel, and copper alloys.

Welding wind turbine towers involves complex conditions, and alignment tolerance is a challenge when welding medium-thickness plates. What products do you recommend to solve these problems?

Welding wind turbine towers involves complex conditions, and alignment tolerance is a challenge when welding medium-thickness plates. What products do you recommend to solve these problems?

Our medium-thickness steel autogenous laser welding system is designed to handle such conditions. Through modular, configurable laser welding software control, the system effectively manages complex working environments and solves the alignment tolerance and welding defect issues associated with medium-thickness plates. It enhances welding quality and effectively reduces common defects like pores, cracks, and undercutting, ultimately improving weld strength and fatigue life.

Can the equipment maintain stable output in harsh industrial environments with high temperatures and dust?

Can the equipment maintain stable output in harsh industrial environments with high temperatures and dust?

The laser's internal water-cooling air conditioner ensures stable operation, and the external optical path and welding head are sealed to guarantee normal function in temperatures up to 40°C. For dust, protective lenses and air knives provide isolation, so it is not a concern during normal use. However, for prolonged periods of disuse, the laser head should be protected to prevent dust from entering.

Is the welding effect reliable for different materials?

Is the welding effect reliable for different materials?

The full-vector optical field-controlled laser, with its excellent beam quality, 10MHz switching frequency, and freely defined spot shape, is ideal for welding various materials. It provides a stable welding process and superior quality for highly reflective materials like purple copper, high-porosity die-cast aluminum, common carbon steel and stainless steel, as well as various combinations of dissimilar materials.

Is the system tolerant of low workpiece gaps and misalignment

Is the system tolerant of low workpiece gaps and misalignment

The custom-defined spot range of the optical field-controlled laser can be up to 1mm, providing greater gap adaptability than conventional lasers within this defined spot range.

Will changes in welding parameters cause significant fluctuations in welding quality?

Will changes in welding parameters cause significant fluctuations in welding quality?

Welding parameters are a critical factor in laser welding, and the process is relatively dynamic. CP Laser provides a multi-parameter dynamic monitoring and closed-loop control solution that ensures stable welding quality even with non-constant welding processes.

Can it effectively control defects such as pores, cracks, and spatter during the welding process?

Can it effectively control defects such as pores, cracks, and spatter during the welding process?

The full-vector optical field-controlled laser's customizable spot shape and 10MHz switching frequency enable high-speed switching in the longitudinal direction of the spot. This optimizes the melt pool's flow field distribution, reducing the occurrence of defects like pores, cracks, and spatter.

What are the consumable costs?

What are the consumable costs?

Consumables in the laser welding process include protective lenses, shielding gas for the melt pool, and circulating cooling water for the laser and welding head. The cooling water is replaced approximately every three months, and the shielding gas consumption is lower than traditional welding methods like TIG welding (per meter of weld length). The overall consumable cost is low. With a suitable process, optical path design, and maintenance, protective lenses can last for several weeks, making their relative cost very low.

How can we develop new process parameters, which usually require time, experience, and technical support?

How can we develop new process parameters, which usually require time, experience, and technical support?

By using multi-sensor real-time monitoring of the welding process, our closed-loop inference system analyzes how process parameters affect welding outcomes. This optimizes the R&D process for adjusting welding parameters. What was once an experience-based process can now be transformed into a machine learning approach driven by neural network inference, significantly enhancing process R&D capabilities and efficiency.

What are the main application scenarios for large-format galvanometer welding?

What are the main application scenarios for large-format galvanometer welding?

It is primarily used for welding thin plates of aluminum alloys, die-cast aluminum, and copper alloys. Common applications include ultra-large-format, high-speed welding of electric vehicle water-cooling plates and battery busbars.

How does the large-format galvanometer welding system establish a protective atmosphere to prevent weld oxidation?

How does the large-format galvanometer welding system establish a protective atmosphere to prevent weld oxidation?

The system is configured with a coaxial spot-following motion system. A protective gas nozzle is carried by this system to synchronously follow the laser spot, ensuring the melt pool is continuously covered by protective gas and preventing oxidation.

How does the large-format galvanometer welding system solve the spot deformation problem caused by the large working area?

How does the large-format galvanometer welding system solve the spot deformation problem caused by the large working area?

The large-format system, in conjunction with a dynamic spot laser, uses vector spot-editing technology to correct for optical deformation. This optimizes the deformed spot back to a normal shape, enabling the galvanometer to operate at its maximum capacity.

What are the advantages of this large-format galvanometer system compared to flying-seam welding or multi-head splicing?

What are the advantages of this large-format galvanometer system compared to flying-seam welding or multi-head splicing?

By leveraging its long focal length and high energy density, the large-format system eliminates the need for complex robotics, flying-seam welding, or multi-head splicing technologies. This results in higher technical maturity, lower cost, higher reliability, and greater integration capability.