We offer fiber lasers and laser welding solutions for laser welding of die-cast aluminum in the automotive industry

- High-Speed Dynamic Beam Laser Welding for Die-Cast Aluminum Alloys

Die-casting is a casting process that uses pressure to create components with high surface finish and precision, making it widely used for complex parts in automotive and aerospace industries. However, due to the high-speed filling of liquid metal and limited gas exhaust, die-cast parts often contain porosity, which makes welding difficult. High-speed dynamic beam laser welding is considered an ideal solution for die-cast aluminum alloys due to its high tolerance for porosity, fast processing speed, and superior weld quality. - Ensuring the Quality of Vacuum Brazing

Due to aluminum alloy's propensity to oxidize and form a high-melting-point aluminum oxide layer on its surface, weld consistency can be affected, and defects like pores can form. Therefore, thorough pre-weld cleaning is essential. During vacuum brazing, the heating process curve must be adjusted based on factors such as high brazing temperature, long overall heating time, high energy consumption of the equipment, and the varying size, shape, and loading method of the workpieces. Ensuring brazing quality requires strict control over process design, pre-weld cleaning, assembly, and in-process management. - The Advantages of Friction Stir Welding (FSW)

Friction Stir Welding (FSW) is a solid-state joining method. Compared to traditional fusion welding, FSW offers several benefits, including lower cost, higher efficiency, fewer weld defects, minimal residual stress, less deformation, better dimensional stability, and a smooth, aesthetically pleasing weld appearance. It is also more energy-efficient and environmentally friendly, with mechanical properties that more closely resemble the base material. FSW is widely used for welding magnesium and, in particular, aluminum alloys.

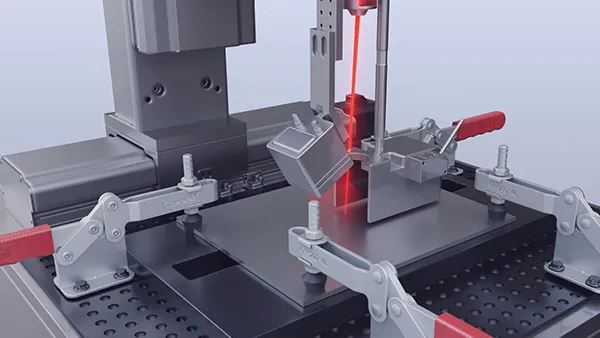

Dynamic Beam Laser Technology Solves Die-Cast Aluminum Welding Challenges

Laser welding, with its concentrated heat source, high depth-to-width ratio, minimal deformation, and ability to perform complex spatial welding, is widely used for multi-layer overlap and high-precision structures. However, it presents multiple challenges for die-cast aluminum, such as strict assembly gap requirements, unstable melt pools due to high reflectivity and a low melting point, and welding defects caused by internal porosity and residual release agents.

Dynamic beam laser technology effectively reduces porosity and improves weld quality by rapidly stirring the melt pool, which provides more space for bubbles to escape. For materials like aluminum and copper, maintaining a stable keyhole during laser deep penetration welding is critical. This can be improved by optimizing laser parameters (wavelength, pulse energy, frequency, feed rate, etc.) and by using beam shaping techniques.

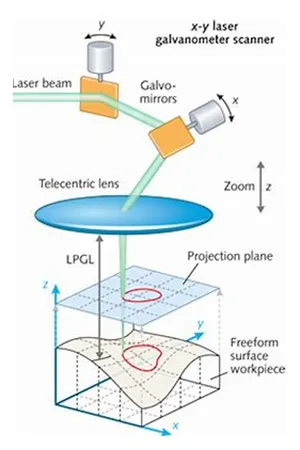

Galvanometer scanning is a widely used technology for rapidly oscillating the output of a single-mode fiber laser in patterns such as circles or figure-eights to create a high-speed oscillating spot. Piezoelectric actuators can be added to the galvanometer scanner to provide a third axis of control, allowing the laser beam's focal point to oscillate in the Z-axis.

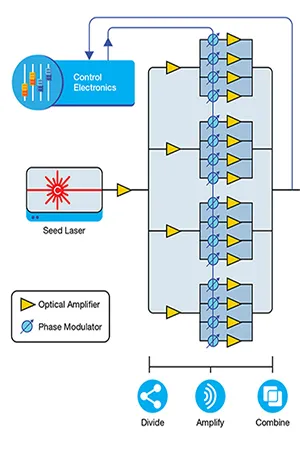

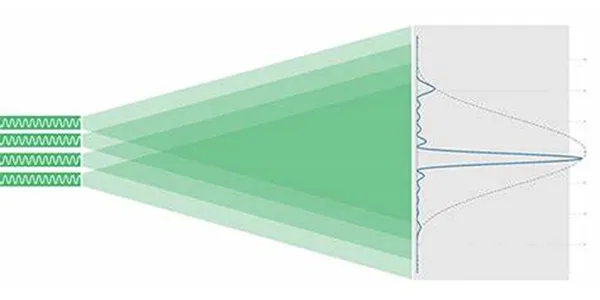

An optical phased array is a coherent beam combining technology that merges multiple single-mode laser beams into a single, larger beam. It uses phase modulators to precisely control the phase of each beam, creating an interference pattern in the far field that enables real-time adjustment of the beam's shape and energy distribution. Compared to traditional beam control methods, phased arrays offer greater flexibility and speed, with modulation frequencies reaching hundreds of megahertz. This allows for stable control of the laser keyhole at ultra-high speeds, which significantly improves welding process stability and weld quality.

Another advantage of dynamic beam shaping is its ability to change the laser's focus. Adjusting the phase interaction not only allows the beam to be moved on a flat XY plane but also to change the focus in the vertical direction. This is the principle behind the coherent dynamic laser beam.

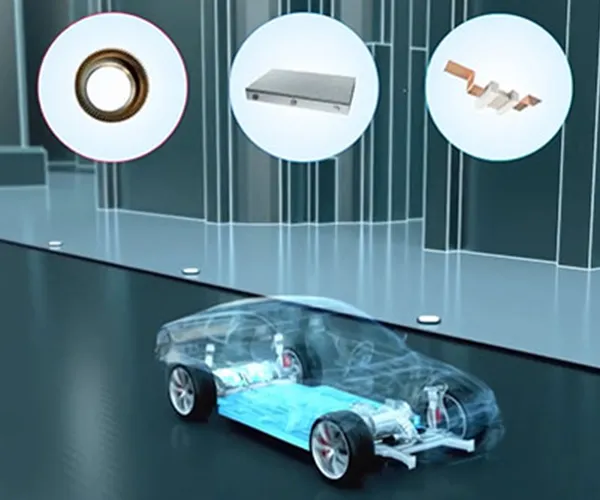

Dynamic Laser Beam Welding for the Liquid Cooling Plate Industry

Cooling systems use a pump to circulate coolant through heat dissipation channels, absorbing heat from power components such as the IGBTs found in electric vehicles and DC power transmission systems.

Demand for die-cast aluminum liquid cooling plates is increasing because they allow for complex flow channels, offer high strength, and can serve as direct mounting plates for battery modules. While friction stir welding offers advantages in efficiency and airtightness, it is limited by design constraints. Traditional laser welding is often challenged by porosity issues. Coherent dynamic laser beam technology effectively addresses this bottleneck, providing a reliable solution for welding die-cast aluminum liquid cooling plates and creating new opportunities in the energy storage industry.