We offer fiber lasers and laser welding solutions for efficient welding of pipelines in the oil and gas industry

Limitations of Traditional Welding

Traditional pipeline welding (primarily arc welding, such as MIG, TIG, and SAW) has long dominated pipeline construction. However, its technical limitations are becoming evident in complex conditions, with high-grade steel pipes, and under strict quality requirements.

- High heat input and degraded performance in the heat-affected zone (HAZ).

- Consistently high weld defect rates.

- Significant quality fluctuations in all-position welding.

- Time-consuming single-pass welding.

- Weak data acquisition and traceability capabilities.

Advantages of Laser Welding

Laser welding offers high precision, high efficiency, and superior weld quality, making it particularly effective for high-pressure petroleum pipelines. Pipelines often traverse mountain slopes, rivers (underwater), and urban buried sections, requiring reliable all-position welding, including flat, vertical, horizontal, and overhead welding.

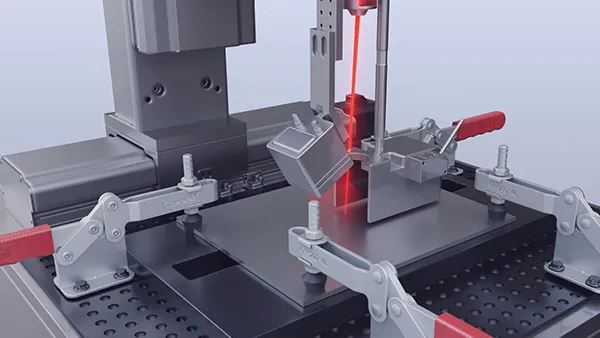

CP Laser has designed a specialized laser welding solution using an all-vector light field modulation laser and multi-sensor real-time monitoring. This allows for real-time adjustment of weld tracking accuracy, enabling high-quality, automated all-position welding.

In petroleum pipeline welding, weld forms are diverse, including circumferential welds, variable cross-section welds, and intersection welds on elbows and tees. The all-vector light field modulation laser uses dynamic phase modulation to generate a spot of any shape in real time, perfectly matching the weld geometry and significantly improving weld strength, durability, and efficiency.