We offer fiber lasers and laser welding solutions for precise and efficient welding of offshore wind towers

The Demand for Narrow Gap Welding in Offshore Wind Towers

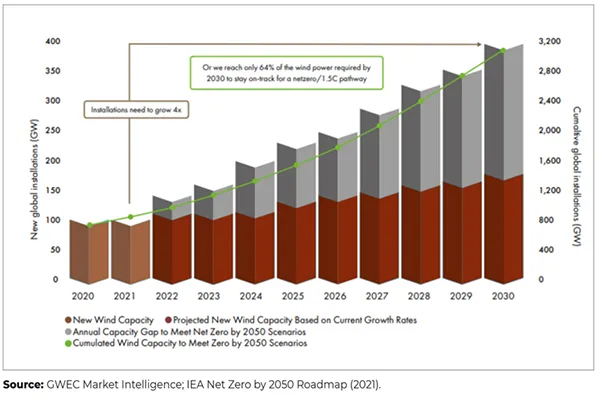

With increasing energy consumption and the growing environmental damage caused by "fossil fuels," global warming is threatening human development. The UN Climate Change Conference has called for accelerating the pace toward achieving "zero emissions" from fossil fuels by 2050. To achieve these goals, large-scale investment in renewable energy is essential, and wind power is set to play a key role.

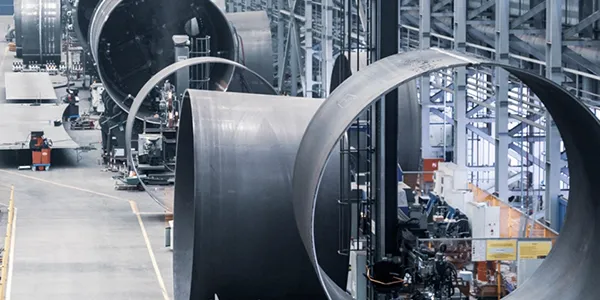

As a clean energy source, the construction of offshore wind towers is growing rapidly. The trend for offshore wind farms is to increase the size of turbines and place them in deeper waters farther from the coast. Turbine dimensions are constantly increasing, with rotor diameters exceeding 150 meters and turbine capacities averaging 7 MW. In deep-sea areas, the impact of waves on structures is uncontrollable, and operating conditions are more severe during storms. This has led to a significant demand for enhanced wind tower safety, which presents unprecedented challenges for manufacturers of such large components and for the welding of thicker steel.

Offshore wind towers are subjected to extremely irregular wind loads and the impact of marine turbulence, which poses a serious threat to their operational safety. Additionally, a large heat input can lead to severe welding deformation, and correcting this deformation is very difficult. Therefore, a smaller weld groove is required to improve heat input control during the welding process and, in turn, ensure the quality of the weld.

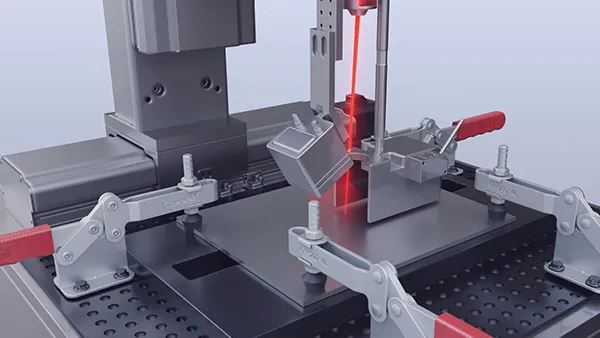

The Laser as a Reliable Tool for Narrow Gap Welding

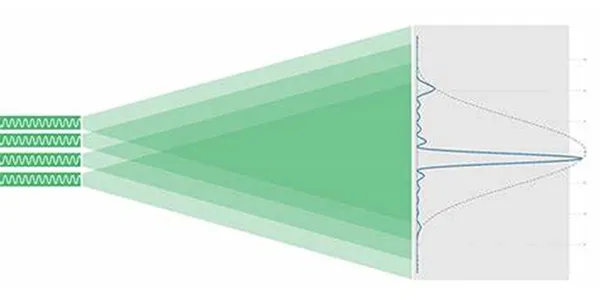

Recent advancements in laser coating technology have improved the laser threshold of reflective mirrors, and laser galvanometers can now handle higher power. This allows for high-power galvanometer oscillating laser focus, which further optimizes the effectiveness of filler wire welding. This technique significantly reduces the likelihood of lack of fusion defects on the side walls in narrow gap welding.

Phased-Array Laser: The Optimal Choice for Thick Plate Welding

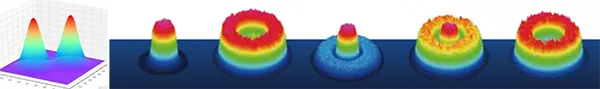

Optical phased arrays are a coherent beam combining technology that merges multiple single-mode laser beams into a larger one. By using a phase modulator to precisely control each beam's phase, an interference pattern is created in the far field, enabling dynamic beam shaping. This provides stable control over the laser keyhole, which significantly improves weld quality.

Another advantage of this technology is the ability to dynamically change the focus position. It can not only move the laser spot in the flat XY plane but also adjust the energy distribution in the Z-axis (depth). This optimizes melt pool flow and heat transfer, reduces the need for multi-layer welding, and lowers the uncertainty caused by residual stress, which ultimately improves the structural fatigue resistance and ensures the safe operation of large structures like offshore wind towers.